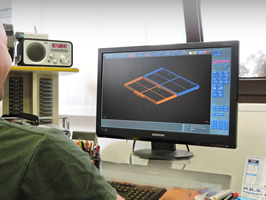

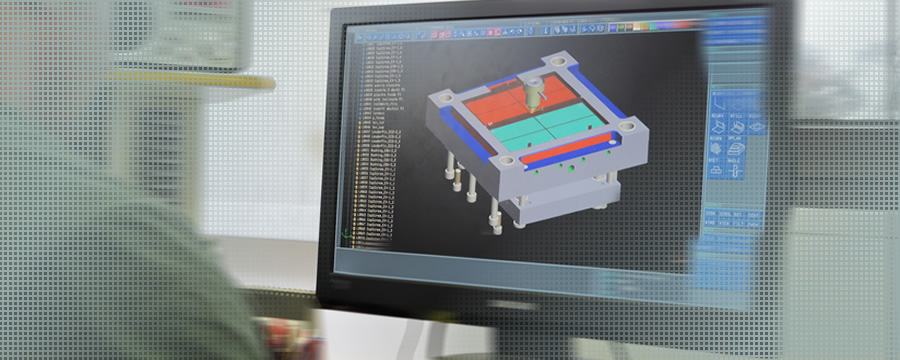

In order to create a good design, every specific request must be fully understood and then satisfied in a single technical response that fully respects dimensional tolerances. In fact, at FEBE computer-aided designing is considered one of our most important and sophisticated activities.

The mold design procedure is exceptionally detailed. Thanks to CAD-CAM systems we can start from any mathematical format, specify it with the client and custom–build the most appropriate equipment to produce the final product.

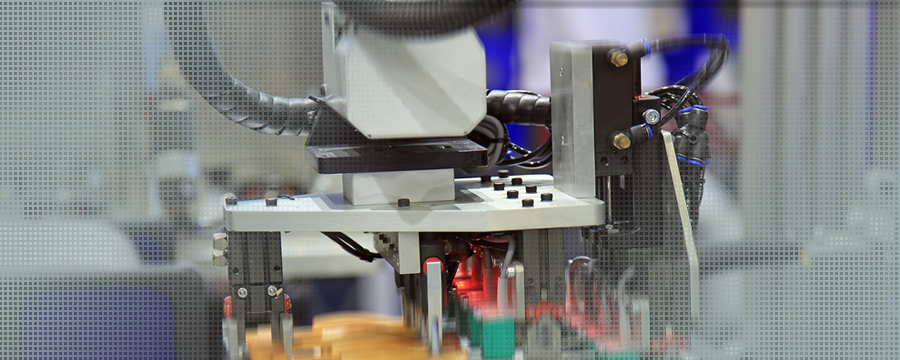

To build the molds we make use of the most specialised firms and the most able to integrate the requitements of the client, and of first-class equipment such as machining centers, CNC milling machines, EDM, manual milling machines, lathes, grinders and auxiliary equipment.

The careful choice of the production material to build the mold, hardened steel, ensure that the molds are able to sustain high volumes of productivity with minimum depreciation.

Maintainance of the moulds at FEBE is a very important process, especially when the moulds are used for high volumes of production. A constant, regular process of cleaning and general maintenance guarantees a high standard of quality in production.

At the end of the production process we will archive the mould in a defined area within our facilities where each mould is clearly marked with the name of the client.