INJECTION MOLDING

Production through injection molds spans across diverse application fields: car, electronic, domestic appliances, health industry, mechanical, thermohydraulic.

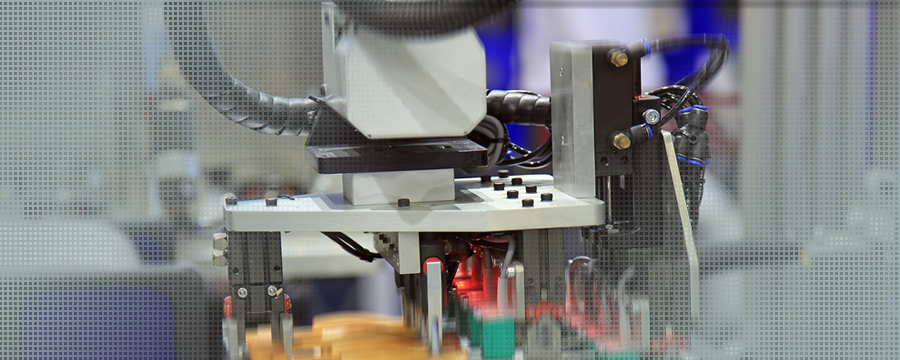

The FEBE machine suite is composed of vertical presses designed for the molding of polymers. Each machine has a dedicated dehumidification system, maintaining the consistency and quality of the plastics they engineer as large quantities of raw materials are transformed.

Particular attention is devoted to selecting gruppi di plastificazione delle presse, the true heart of the machines, with dedicated profiles for the various families of materials and a growing number of groups that are highly resistant to wear and corrosion – allowing us to process composite materials more efficiently. FEBE also provides auxilliary equipment such as mold temperature control units (ensuring maximum repeatability of the production cycle), manipulators and various tools to tackle common production problems.

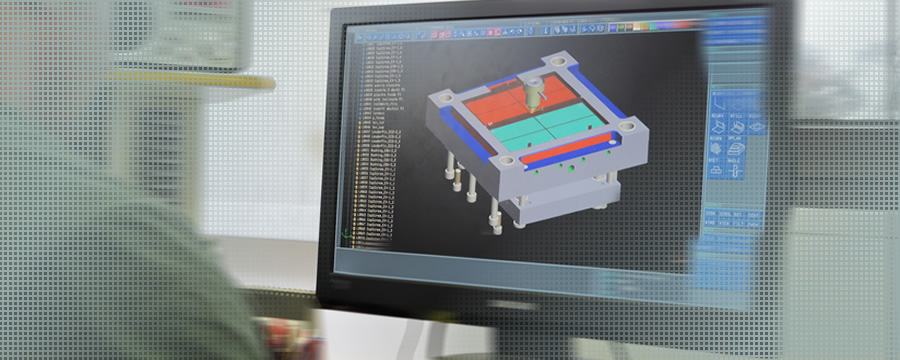

Productivity is monitored in real time with an accurate automated data collection system managed by a complete resource management solution.

Our Injection Molding products mainly include:

Automotive: gasoline and oil filters.

Health: medical and filters for infusion.

Electronics: filters for smoke detection and fire.